GoodCut GC-WCC 4in1 Hot Sale Laser Welding Cleaning Cutting Machine Double Wire Feeder Clean Welded Track

Specifications |

Model | GC-WCC 4in1 |

Functions | Welding , cleaning ,cutting, clean welded track |

Fiber Laser source | MAX /Raycus 1500w 2000w 3000w |

Spare parts | Focus lens and Protective lens only |

Machine head | AU3TECH |

Control system | AU3TECH |

Wire feeder | AU3TECH |

Machine appearance | GoodCut |

Laser wavelength | 1064nm |

Working min molten pool | 0.1mm |

Working depth | ≤3mm |

Spot size adjustable range | 0.3-3.0mm |

Workbench repeatability | ±15kw |

Viewing system | Red light positioning |

Cooling | Water cooling |

Operating Temperature | 0-45℃ |

Operating humidity | 5%-95% |

Warranty | Two years |

Voltage | 220V/380V; 50HZ/60HZ; 1Phase/3Phase |

Packing | Seaworthy wooden case with vacuum packing, tinfoil and metal frame inside. |

Technical Support and After-sales service: |

DOCUMENTATION The following documentation is supplied with the machine: Copies of the Machine Instruction Manual CE conformity declaration. Delivery Protocol. Software manual. USB driver for backup. WIFI instant detecting and fast problem confirming. |

After-sale services To provide customers with all aspects of service. We guarantee: 2 years warranty of machine. Feedback within 5 hours with solutions for every problem. Machine lifetime maintenanceservices though warranty expires. Wide range of hardware and software support after the warranty expires, enjoy free upgrades. |

Feature:

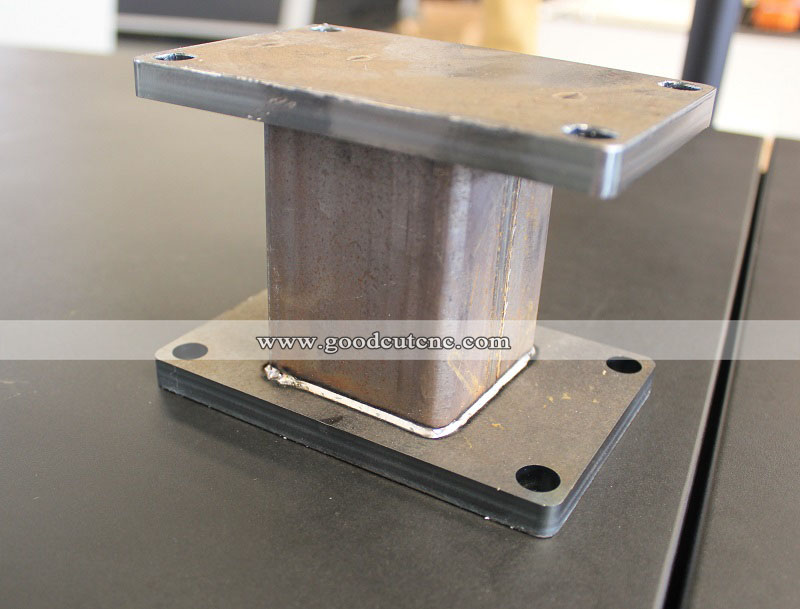

1. The weld seam is smoothe and beautiful, it doesnot need to be polished or the workboard of the polish is very small.

2. Through control the laser energy, the welding will not defrom or very few deformation.

3. Handheld laser welding machine is easy to handle and needn't to require the professional welders.

4. The wobble welding machine can handle the hard welding material easily, such as aluminum, brass.

5. Long life span up to 100,000 hours and low comsumption.

6. the Auto wire feeding handheld welding machine can weld parts with wider gap.

7. With a 8-15m fiber line, It can weld long-distance and large- area parts.

8. Various welding processes, such as spot welding, seam welding and overlap welding.

9. The welding efficiency is around 5 times of TIG welding.

10. It is welding used in electronics, sheet metal, air condiction industry etc.

Deatiled parts:

1. Automatic Wire feeder

No consumables, small size, flexible processing, low operating and maintenance costs.

2. Water Chiller

High cooling rate, which can weld fine weld structure and good joint performance.

3. Laser Welding / Cutting / Cleaning Head

Smart high frequency swing welding head. Can be widely used in metal equipment, stainless steel home and other industries complex irregular welding process.

Also can do cutting and cleaning work, just change differnet head.

4. Laser Source

Chinese top brand fiber laser source Raycus, high power. The energy density is high, the heat input is low, the amount of thermal deformation is small.

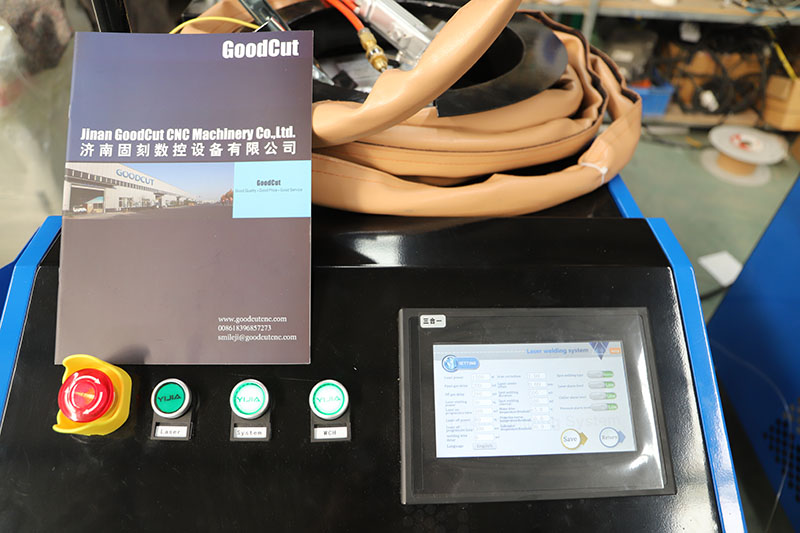

5. Control Panel

With auto layout optimization, ensure high speed operation of whole machine.

Application:

1. Material

Stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials, such as: copper - brass, titanium - molybdenum, titanium - gold, nickel - copper and so on.

2. Welding,Cleaning,Cutting

Kitchen cabinets, staircase elevator, shelf, oven, stainless steel door, window guardrail, distribution box, medical equipment, communications equipment, craft gifts, household and other industries.

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 500 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.